-

APLC (Cartridge) Dust Collector

-

HI-VAC 1500 SERIES Hi Vacuum Dust Collectors

-

AEW Airtight Extraction Wall

-

AST Airtight Suction Table

-

CDS Series School Shaker Dust Collector

-

Dust Vacuum Wand Kit

$209.00 -

5 Metre Dust Vacuum Wand Kit

$555.00 -

10 Metre Dust Vacuum Wand Kit

$766.50 -

Exhaust Reels

-

RFA Digester fans

-

CNC Flex

$137.80 – $193.95 / m -

APMP Pulse Jet Dust Collector (Wide Pleated Elements)

-

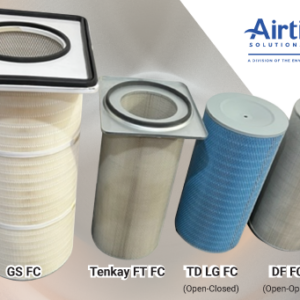

Filter Cartridges

$177.00 – $490.00 -

Plastic Dust Collector Bags

$124.00 – $140.00 -

APMB Pulse Jet Dust Collector (Tubular Filter Bags)

-

Timberflex Medium

$37.70 – $191.20 / m

Menu

Menu